We have developed test inventory as an analysis of mental models on heat and temperature topics. Berdasarkan analisis data, instrumen tes model mental pada materi suhu dan kalor layak digunakan sebagai instrumen penilaian. Tes yang telah dikembangkan terdiri dari 8 soal dengan reliabilitas sebesar 0,667. Selanjutnya, instrumen tes model mental diujicobakan kepada responden (N=90) untuk mengukur validitas dan reliabilitas. Produk yang dihasilkan merupakan instrumen analisis model mental berupa soal terbuka. Penelitian ini menggunakan model pengembangan 4-D. Model mental merupakan representasi internal siswa dalam memahami sebuah konsep. Penelitian pengembangan ini didasarkan pada pentingnya mengetahui tingkatan model mental siswa. Kami telah mengembangkan tes sebagai analisis model mental pada materi suhu dan kalor. PENGEMBANGAN INSTRUMEN MODEL MENTAL PADA TOPIK SUHU DAN KALOR Considering the level of complexity and accuracy, a mathematical process model of steady-state two parallel plug flow reactors was proposed as the optimum solution for the mathematical description of enzymatic biodiesel synthesis performed in a microreactor. Two out of three proposed mathematical process models described experimental data very well for all analysed residence times. In comparison to the batch process, where the yield of 96% was achieved for 48 h, this was a significant improvement. If a large excess of methanol was used (oil to methanol ratio 1:90) the yield was higher than 90% for the residence time of only 40 min.

An increase of biodiesel yield was observed for the higher methanol concentration in the system.

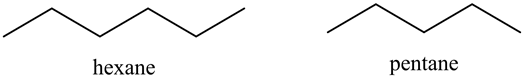

MMASS OF HEXANE FREE

In all validation experiments, free fatty acid concentration and enzyme concentration were kept constant and the oil to methanol ratio in the inlet streams was altered. In order to validate the proposed mathematical process models, biodiesel synthesis in a microreactor was performed at four different initial process conditions. The Hill kinetic model was proposed as the best kinetic model based on the model selection criterion. Prior to transport model development, the reaction rates were described with double substrate Michaelis-Menten kinetics, Bi-Bi Ping-Pong kinetics, and Hill kinetics. Therefore, three additional mathematical process models were proposed. Based on the experimental results and model simulation it was shown that Bi-Bi Ping Pong mathematical process model is not suitable for the description of the lipase catalysed biodiesel production in a microreactor.

0 kommentar(er)

0 kommentar(er)